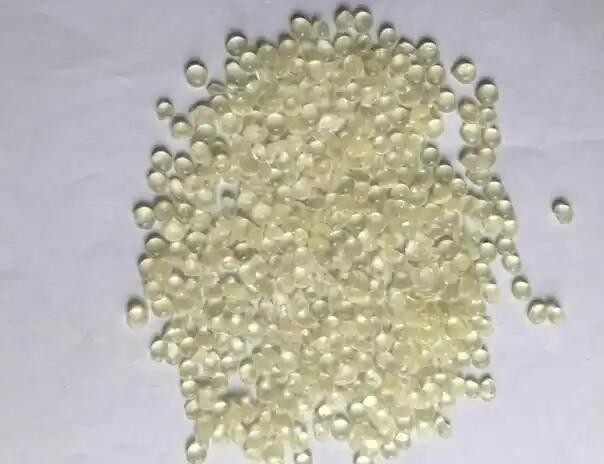

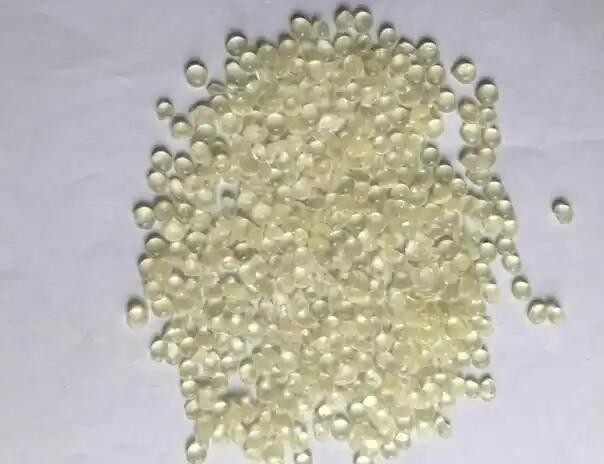

Light-colored resin is a type of synthetic resin with low chromaticity,high transparency,or light appearance,widely used in coatings,inks,adhesives,plastic modification,and other fields.Its core characteristic is to achieve a light color effect that traditional resins cannot achieve through chemical structure optimization or additive regulation,while maintaining or improving the mechanical properties,weather resistance,and chemical stability of the material.The technological evolution of light-colored resins,from petroleum based thermoplastic resins to natural terpene polymers,is driving downstream industries towards high added value and environmental protection.

1.Definition and source:Dual pathway of chemical synthesis and natural modification

Light-colored resin is not a single substance,but a general term for light colored or transparent polymer materials prepared through specific processes.Its sources can be divided into two categories:

(1)Chemical synthesis type:Made from petroleum cracking by-products(such as C5 and C9 fractions)as raw materials,through catalytic polymerization or hydrogenation reactions.For example,C5 hydrogenated petroleum resin is polymerized by cracking the diene and monoolefin in the C5 fraction,followed by hydrogenation decolorization to obtain a water white transparent resin.

(2)Natural modified type:Made from natural resin(such as rosin)as raw material,modified through dimerization,esterification and other reactions.For example,dimeric rosin is selectively dimerized between rosin acid molecules,with a significantly increased softening point and a lighter color than ordinary rosin.

2.Classification and Representative Products:Diversified System with Functional Orientation

According to the composition and process,light-colored resins can be classified into the following types:

(1)Light colored petroleum resin:Made from low-carbon components through catalytic polymerization,it has water and acid alkali resistance,but weak adhesion.It is often mixed with other resins to improve performance.

(2)Hydrogenated terpene resin:made by polymerizing terpene compounds(such as d-limonene)and hydrogenation,it has the characteristics of low odor,high stability,and aging resistance,and is widely used in pressure-sensitive adhesives and hot melt adhesives.

(3)Dimerized rosin resin:generated by highly dimerized rosin,with high softening point and strong antioxidant properties,suitable for coatings,inks,and electronic packaging fields.

(4)Acyclic hydrogenated resin:such as cycloaliphatic hydrogenated C5/C9 copolymer resin,with extremely light color and excellent transparency,commonly used in high-end adhesives and sealants.

3.Core feature:Balance art between light color and performance

The outstanding advantage of light-colored resin lies in the synergistic optimization of its physical and chemical properties:

(1)Low chromaticity and high transparency:impurities are removed through hydrogenation,refining and other processes,and the color number can be as low as 1 or less(Gardner chromaticity),meeting the strict requirements for appearance in application scenarios.

(2)Thermal stability and weather resistance:Hydrogenation treatment can reduce the content of unsaturated bonds,enhance the UV resistance and high-temperature stability of light-colored resins,and expand their applicability to outdoor environments.

(3)Compatibility and solubility:It can be well mixed with various resins and solvents such as EVA,SBS,polyester,etc.,making it easy to compound and optimize the performance of end products.

(4)Functional adjustability:By adjusting the molecular structure or copolymer composition,the softening point,viscosity,hardness and other parameters of light-colored resins can be customized to meet differentiated needs.

4.Typical application:Multi functional solutions across industries

Light-colored resin has become a key material in various fields due to its comprehensive properties

(1)Adhesives and sealants:As thickening agents for hot melt adhesives and pressure-sensitive adhesives,they enhance bonding strength and heat resistance,and are widely used in industries such as packaging,automotive,and electronics.

(2)Coatings and inks:Improve the hardness,water resistance,and printing adaptability of paint films,used for high-end coatings,UV inks,and special printing.

(3)Electronic packaging:As a modifier for epoxy resin,it enhances the moisture resistance and insulation properties of packaging materials,ensuring the reliability of electronic components.

(4)Rubber and Plastic:As a softener or tackifier,it optimizes the flexibility of rubber products and the processing performance of plastics.

The research and application of light-colored resins have broken through single performance optimization and shifted towards multifunctional collaborative development.For example,reducing the unsaturation of C5/C9 petroleum resin through hydrogenation modification can simultaneously enhance its resistance to yellowing and adhesive strength;Terpene resin utilizes natural terpene monomers to polymerize and enhance biocompatibility while achieving light coloration.In the future,with the breakthrough of nano filler dispersion technology and light stabilizer composite process,light-colored resins will show broader application prospects in high-end coatings,food packaging,optical films and other fields,becoming an important innovation direction in the field of materials science.

Language

▼

Language

▼

Address:Linzi District,Zibo City,Shandong Province

Address:Linzi District,Zibo City,Shandong Province E-mail:wanbang@wanbangresin.com

E-mail:wanbang@wanbangresin.com WhatsApp:+8615053337101

WhatsApp:+8615053337101