Language

▼

Language

▼

More Language

Technical analysis of light-colored resins

I. Main types and raw materials

Rosin-modified maleic acid resin:

Using rosin and maleic anhydride as raw materials, it is light yellow flake-like and has good heat resistance (softening point ≥ 100°C). It is suitable for the manufacture of light-colored oil-based resin paints, metal anticorrosive coatings and ink plasticizers. Its products are not easy to turn yellow and have high paint film hardness.

Adding 5-15% can significantly improve the gloss and water resistance of inks, and reduce the amount of vegetable oil in coatings (saving more than 10%).

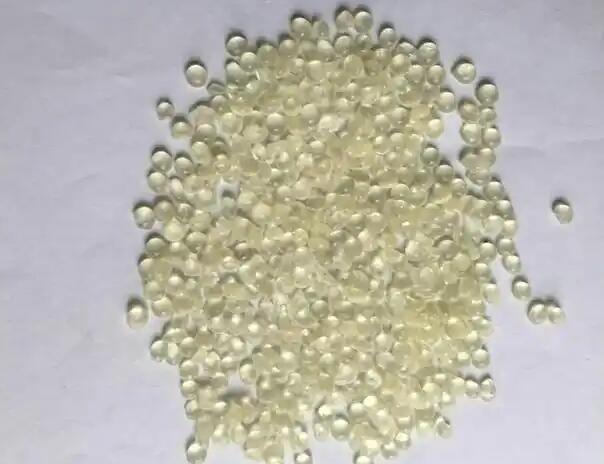

Light-colored petroleum resin:

Using low-carbon components of petroleum cracking by-products as raw materials, it is made by catalytic polymerization. It has light color (color number ≤ 6#), does not contain polar groups, has excellent water resistance, acid and alkali resistance, but has weak mechanical strength and adhesion, and needs to be compounded with epoxy resins.

Typical products such as C5/C9 copolymer resins are soluble in hydrocarbon solvents and are suitable for mid-range paints, road sign paints and inks.

Light-colored rosin resin:

As a tackifier in hot melt adhesives and pressure-sensitive adhesives, it improves initial adhesion and substrate adhesion (peel strength increased by 20-30%), and is also used in rubber products to improve elasticity and bonding strength.

2. Core performance advantages

Optical properties:

Light-colored resin has stable chromaticity (whiteness ≥ 90%), and is suitable for coatings and inks with high transparency requirements, such as electroplating varnish, jewelry protective paint, etc.

Chemical resistance:

Light-colored petroleum resin has excellent acid and alkali resistance (no corrosion for 48 hours), and rosin-modified resin has a temperature resistance of up to 150°C, meeting industrial anti-corrosion needs.

Environmental adaptation:

RoHS certified, VOC content <50 g/L, some models support food contact scenarios (such as FDA certification).

3. Application scenarios and selection recommendations

Coating field:

Light-colored oil-based paint: Rosin-modified maleic acid resin and alkyd resin are compounded, suitable for wood and metal surface protection, and the paint film hardness ≥H grade.

Epoxy anticorrosive paint: Light-colored petroleum resin is mixed with epoxy E-20 resin to improve water resistance and reduce raw material costs.

Ink and adhesive:

Printing ink: Light-colored rosin resin is used as a plasticizer to enhance the fast fixation of ink and the gloss of printed products.

Hot melt adhesive: Light-colored petroleum resin (softening point 80-120℃) optimizes colloid fluidity and is suitable for packaging, book binding and other scenarios.

Rubber and building materials:

Light-colored resin is used for softening and modification of rubber products to improve tear resistance (tensile strength increased by 15%), or as a concrete foaming agent to improve the lightweight effect of building materials.

Address:Linzi District,Zibo City,Shandong Province

Address:Linzi District,Zibo City,Shandong Province E-mail:wanbang@wanbangresin.com

E-mail:wanbang@wanbangresin.com WhatsApp:+8615053337101

WhatsApp:+8615053337101

China C5 hydrogenated petroleum resin supplier : Shangdong Wanbang New Materials Co., Ltd.

C5 hydrocarbon resin manufacturer has a wide range of applications, high quality, low price, and multiple uses.Welcome to consult.