Language

▼

Language

▼

More Language

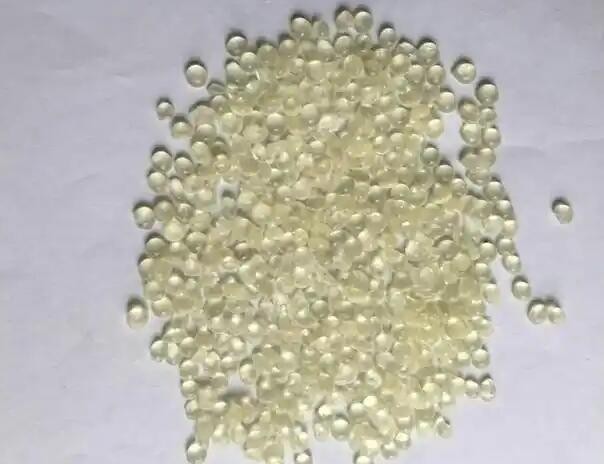

Recently, significant breakthroughs have been made in the preparation method of light-colored carbon nine petroleum resin, laying a solid foundation for the widespread application of this high-performance material. With its unique physical and chemical properties, it has shown great potential for applications in various fields such as coatings, adhesives, rubber, and printing inks. This innovation in preparation technology not only improves production efficiency, but also further optimizes its performance, enabling it to better meet market demand. The preparation method of light-colored carbon nine petroleum resin mainly includes the following steps:

The main raw material for light-colored carbon nine petroleum resin is the by-product C9 fraction from the ethylene cracking unit. This fraction has a complex composition and contains over 150 detectable components, but the effective polymerization components are mainly active components with unsaturated bonds, such as styrene, dicyclopentadiene, methylstyrene, vinyl toluene, indenes, etc. To ensure the quality of the finished product, it is necessary to use cracked C9 fractions with high cyclopentadiene content.

Before synthesis, it is necessary to pre treat the raw materials, including dehydration, desulfurization, and removal of other impurities, to ensure high purity and efficiency in subsequent reactions. The preprocessing system uses a primary distillation tower and a distillation tower to refine the C9 fraction. First, atmospheric distillation is carried out in the primary distillation tower to cut out the lower boiling fractions, which can be used as solvents in industries such as coatings and adhesives. Then the heavy components separated from the initial distillation tower enter the distillation tower, and the refined C9 fraction with a distillation range of 70-186 ℃ is extracted using vacuum distillation as the raw material for polymerization.

The polymerization reaction is a key step in the preparation process of light-colored carbon nine petroleum resin. In the presence of a catalyst, the active components in the refined C9 fraction undergo polymerization reactions to produce resin. Common catalysts include boron trifluoride ether complexes, etc. The amount of catalyst used is 0.1-0.6% of the total weight of monomers in the raw oil. The polymerization temperature is generally controlled within a certain range, and the higher the temperature, the lower the molecular weight, and the color deteriorates accordingly. The average residence time also needs to be controlled properly. The longer the residence time, the higher the resin yield, but the amount of low molecular weight polymer generated will also increase, the softening point will decrease, and the volatile components will also increase accordingly.

After the polymerization reaction is completed, it is necessary to remove the catalyst from the polymer material. The traditional methods are alkaline washing and water washing, but this method has emulsification problems, making it difficult to remove the catalyst and generating a large amount of wastewater that pollutes the environment. To solve this problem, phosphites and homemade additives can be used as catalyst terminators, and then the catalyst can be removed by filtration. This method avoids emulsification and the generation of a large amount of wastewater, and the obtained petroleum resin has a relatively light color.

After removing the catalyst, the polymerization solution needs to be distilled to remove unreacted substances and low boiling point components, resulting in crude resin. Crude resins usually require further refining to remove unreacted monomers and low molecular weight by-products. Common refining methods include distillation and extraction. The refined resin has the desired purity and molecular weight.

Address:Linzi District,Zibo City,Shandong Province

Address:Linzi District,Zibo City,Shandong Province E-mail:wanbang@wanbangresin.com

E-mail:wanbang@wanbangresin.com WhatsApp:+8615053337101

WhatsApp:+8615053337101

China C5 hydrogenated petroleum resin supplier : Shangdong Wanbang New Materials Co., Ltd.

C5 hydrocarbon resin manufacturer has a wide range of applications, high quality, low price, and multiple uses.Welcome to consult.