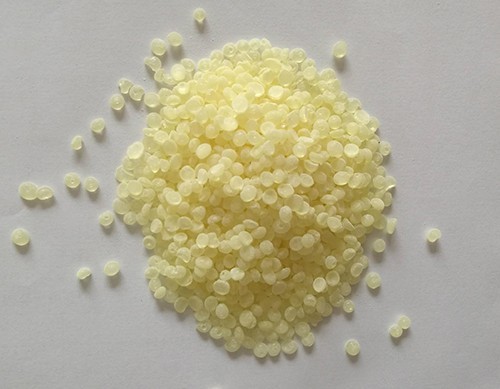

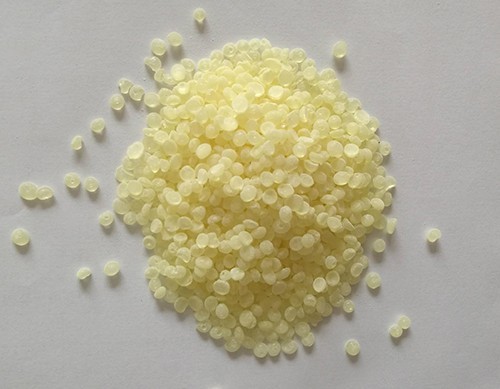

The curing process of hot melt adhesive special resin for hot melt adhesive is a key link in the application of hot melt adhesive, which determines the key properties such as adhesive strength, heat resistance, and chemical resistance of hot melt adhesive. The following is a detailed analysis of the curing process of hot melt adhesive special resin manufacturer:

1. Overview of curing process

After being heated to a certain temperature, the hot melt adhesive special resin for hot melt adhesive changes from solid to liquid, making it easy to coat on the adhesive substrate. After coating, as the temperature decreases, the resin molecular chains begin to rearrange and form a stable solid structure, thereby achieving curing. During this process, the physical state and chemical properties of the resin will undergo significant changes.

2. Curing type

The curing process of hot melt adhesive special resin can be divided into two types: physical curing and chemical curing, depending on the type and formula of the resin.

1. Physical curing:

Process description: Physical curing mainly relies on the physical cross-linking of resin molecular chains during cooling to form a stable solid structure. This curing process does not involve chemical reactions, so the speed is fast, and the cured hot melt adhesive has a certain reversibility, that is, it can be reheated and melted under certain conditions.

Application example: The curing process of non reactive polyurethane hot melt adhesive belongs to physical curing. This type of hot melt adhesive is coated on the adhesive substrate after heating and melting, and can solidify after cooling, with good initial adhesion.

2. Chemical curing:

Process description: Chemical curing involves the chemical reaction between the active groups in resin molecules and moisture in the air, water attached to the surface of the adhesive, or other active substances, forming a cross-linked network structure. This curing process is slower, but the cured hot melt adhesive has higher adhesive strength, heat resistance, and chemical resistance.

Application example: The curing process of reactive polyurethane hot melt adhesive belongs to chemical curing. This type of hot melt adhesive is coated on the adhesive substrate after heating and melting, and obtains initial adhesive strength after cooling; Subsequently, the active NCO groups in the adhesive layer react with moisture in the air, resulting in chemical cross-linking and curing, significantly improving the adhesive performance.

3. Curing conditions

The curing process of hot melt adhesive special resin is affected by various conditions, mainly including temperature, pressure, humidity, and time.

Temperature: Temperature is a key factor affecting the curing speed. Generally speaking, the higher the temperature, the faster the curing speed; However, excessive temperature may cause defects such as resin decomposition or the formation of bubbles. Therefore, it is necessary to set the appropriate curing temperature according to the type and requirements of the hot melt adhesive during the production process.

Pressure: Appropriate pressure helps to promote the tight arrangement of resin molecular chains and the occurrence of cross-linking reactions, thereby improving the adhesive strength after curing. However, excessive pressure may cause deformation or damage to the substrate.

Humidity: For chemically cured hot melt adhesives, humidity is an important factor affecting the curing speed. Moisture in the air or moisture attached to the surface of the adhesive can participate in the curing reaction, accelerating the curing process. However, excessive humidity may cause defects such as resin moisture absorption and expansion, or the formation of bubbles.

Time: Curing time refers to the length of time that hot melt adhesive takes from liquid to fully cured. Short curing time may lead to poor bonding effect; If the curing time is too long, it may reduce production efficiency. Therefore, it is necessary to set an appropriate curing time based on the type and requirements of the hot melt adhesive.

4. Performance after curing

The cured hot melt adhesive special resin has excellent adhesive properties, heat resistance, cold resistance, stability, and chemical resistance. These properties make hot melt adhesives widely used in packaging, shoemaking, electronics, construction and other fields.

In summary, the curing process of hot melt adhesive special resin for hot melt adhesive is a complex and critical process, which directly determines the adhesive performance and usage effect of hot melt adhesive. Therefore, it is necessary to strictly control the curing conditions during production and use to ensure the quality and performance of hot melt adhesive.

Language

▼

Language

▼

Address:Linzi District,Zibo City,Shandong Province

Address:Linzi District,Zibo City,Shandong Province E-mail:wanbang@wanbangresin.com

E-mail:wanbang@wanbangresin.com WhatsApp:+8615053337101

WhatsApp:+8615053337101