Language

▼

Language

▼

More Language

Technical analysis of petroleum resin for hot melt adhesive

I. Main types and characteristics

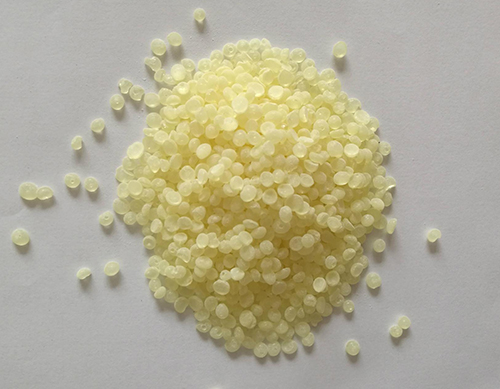

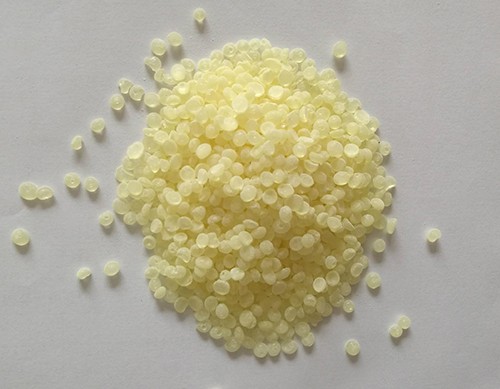

C5 petroleum resin:

It is made from cracked carbon five fractions through cationic polymerization or hydrogenation process, with low color number (transparent to light yellow) and softening point of 80-120℃.

It has excellent compatibility with thermoplastic elastomers such as SBS, SIS, and EVA, and can improve the initial adhesion and peel strength of hot melt adhesives. It is suitable for sanitary products, packaging materials and other fields.

C9 petroleum resin:

It is made from carbon nine fractions, has a high softening point (110-140℃), outstanding temperature resistance, and is often used in high temperature resistant hot melt adhesive formulations (such as automotive sealants and industrial adhesives).

It needs to be compounded with C5 resin or elastomer to balance bonding strength and processing fluidity.

C5/C9 copolymer resin:

Combining the advantages of C5 and C9 fractions, it has both low chroma and high temperature resistance, and is suitable for high-end hot melt pressure-sensitive adhesives (such as label tapes and medical patches).

Liquid C5 petroleum resin (such as Wingtack series) can reduce the melt viscosity of hot melt adhesive and improve the adaptability of spraying process.

Hydrogenated modified resin:

The hydrogenation process significantly reduces the resin color (near colorless) and odor, meeting the environmental protection requirements of food contact and medical grade adhesives (VOC < 50 ppm).

For example, C5 hydrogenated resin DR-5300 has improved aging resistance and is suitable for maternal and child products and outdoor weather-resistant adhesives.

2. Core performance advantages

Tackification efficiency:

Petroleum resin can replace more than 60% of rosin or terpene resin, reducing the formulation cost while maintaining bonding performance (peel strength ≥ 2.5 MPa).

Thermal stability:

High temperature resistance up to 150°C, stable melt viscosity (500-3000 mPa·s), suitable for high-speed coating process.

Environmental adaptation:

Passed RoHS and PAHs certification, some models support FDA food grade applications (such as sanitary napkins, diaper adhesive layer).

3. Application scenarios and formula design

Sanitary products:

C5 hydrogenated resin (such as 5300 model) with an addition amount of 10-20% is used for traceless bonding of disposable non-woven products, with an initial adhesion of ≥10 N/cm².

Packaging and label adhesive:

C5/C9 copolymer resin is compounded with SBS to optimize the quick drying and low temperature resistance of hot melt adhesive (no brittle cracking at -20℃), suitable for frozen food packaging.

Industrial adhesive:

High softening point C9 resin (such as PuLe Chemical Customized Series) is used for tire cord adhesive and electronic component packaging adhesive, and the dynamic fatigue life is extended by 30%.

Address:Linzi District,Zibo City,Shandong Province

Address:Linzi District,Zibo City,Shandong Province E-mail:wanbang@wanbangresin.com

E-mail:wanbang@wanbangresin.com WhatsApp:+8615053337101

WhatsApp:+8615053337101

China C5 hydrogenated petroleum resin supplier : Shangdong Wanbang New Materials Co., Ltd.

C5 hydrocarbon resin manufacturer has a wide range of applications, high quality, low price, and multiple uses.Welcome to consult.