Language

▼

Language

▼

More Language

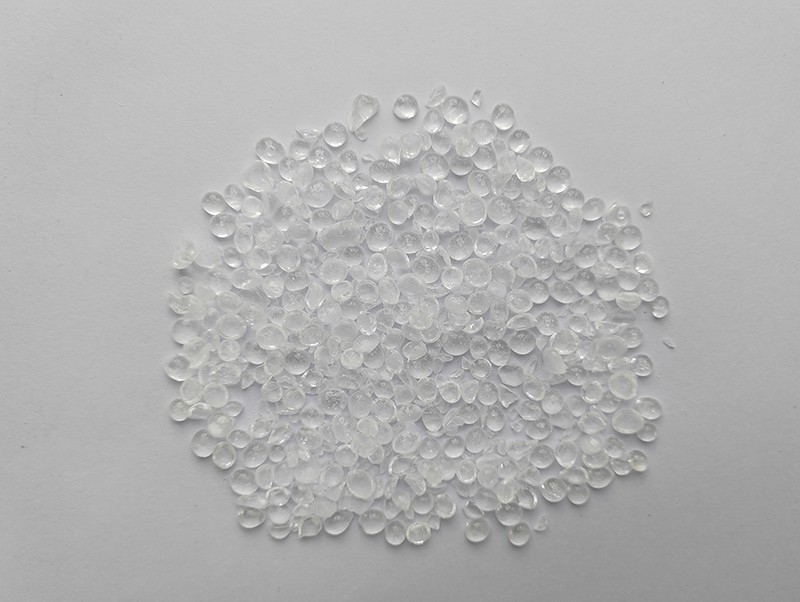

In the field of adhesive manufacturing, glue resin, as a key raw material, is playing an increasingly important role. Recently, the core position and multiple functions of glue resin in adhesive manufacturing have attracted widespread attention in the industry. Resin not only provides strong adhesive strength for adhesives, but also endows them with excellent physical and chemical properties. As an important component of adhesives, there are various types of glue resins, including natural resins and synthetic resins, each of which plays an irreplaceable role in the manufacturing process of adhesives. With the advancement of technology and the development of the industry, the application scope of glue resin is constantly expanding. From traditional wood processing and paper bonding to modern fields such as electronics and aerospace, glue resin has demonstrated its unique advantages and value.

Resin is the main adhesive component in glue, which can firmly bond different materials together through chemical bonds, physical adsorption, or a combination of both. Different types of resins have varying degrees of adhesion to different materials. Therefore, when selecting adhesive, it is necessary to choose the appropriate type of glue resin based on the type and characteristics of the material being bonded.

Glue resin not only provides adhesion, but also enhances other properties of the adhesive, such as heat resistance, cold resistance, water resistance, chemical corrosion resistance, etc. These performance enhancements enable the adhesive to remain stable under a wider range of environmental conditions and meet various application requirements. For example, epoxy glue resin has excellent heat resistance and chemical corrosion resistance, and is commonly used in fields that require high strength and long-lasting bonding effects; Polyurethane resin is often used to manufacture elastic adhesives due to its good elasticity and wear resistance.

The molecular structure and molecular weight of resin have a significant impact on the viscosity of adhesives. By adjusting the type and amount of resin, the viscosity of the adhesive can be easily adjusted to meet the needs of different application scenarios. For example, in situations where rapid coating and curing are required, low viscosity resins can be chosen to prepare adhesives; In situations where viscosity needs to be maintained for a longer period of time, high viscosity resins can be chosen.

The addition of glue resin can also improve the processing performance of the adhesive, such as increasing the fluidity, wettability, and dispersibility of the adhesive. These performance improvements help the glue to better contact and bond with the adhesive material during coating, curing, and other processing processes, thereby improving the bonding effect.

Address:Linzi District,Zibo City,Shandong Province

Address:Linzi District,Zibo City,Shandong Province E-mail:wanbang@wanbangresin.com

E-mail:wanbang@wanbangresin.com WhatsApp:+8615053337101

WhatsApp:+8615053337101

China C5 hydrogenated petroleum resin supplier : Shangdong Wanbang New Materials Co., Ltd.

C5 hydrocarbon resin manufacturer has a wide range of applications, high quality, low price, and multiple uses.Welcome to consult.