Language

▼

Language

▼

More Language

Analysis of resin technology for glue

I. Main resin types and characteristics

Epoxy resin glue

Basic performance: With epoxy group as the core, it forms a three-dimensional cross-linked structure after curing. It has high bonding strength to metal, glass, ceramic and other materials (peel strength ≥3.0 MPa), and has excellent acid, alkali and water resistance.

Sub-types:

Water-based epoxy resin: VOC content <50 g/L, suitable for environmentally friendly scenarios (such as food packaging), and non-toxic through type I (solvent-free) or type II (containing trace NHAP solvent) system.

High temperature resistant epoxy resin: compounded with silicone modified resin and multifunctional curing agent, with a temperature resistance of more than 250°C, used for electronic component packaging and high temperature environment bonding.

Polyurethane resin glue

It has both flexibility and wear resistance, suitable for bonding flexible materials such as leather and fabrics, stable performance at low temperature curing (-10°C), and excellent yellowing resistance (ΔE <2.0@UV aging 500h).

Environmentally friendly urea-formaldehyde resin glue

Using modified urea-formaldehyde resin as the base material, the formaldehyde emission is less than 0.1 mg/L (GB 18583-2008 standard), and the water resistance is improved by the composite curing agent (water immersion resistance ≥48 hours), which is mainly used in the wood processing industry.

2. Application scenarios and functional adaptation

Electronic industry :

High temperature resistant epoxy resin glue is used for chip packaging and sensor bonding, and has stable performance with cold and hot cycles (-40~250℃), and thermal conductivity ≥1.5 W/(m·K).

Environmentally friendly packaging :

Water-based epoxy resin glue is used for paper/plastic food packaging bonding, and has passed FDA food contact material certification, and there is no migration risk after curing.

Construction and automobile :

Epoxy resin structural adhesive is used for concrete repair and lightweight bonding of car bodies, with impact strength ≥20 kJ/m² and supports rapid curing (surface dry ≤30 minutes).

Address:Linzi District,Zibo City,Shandong Province

Address:Linzi District,Zibo City,Shandong Province E-mail:wanbang@wanbangresin.com

E-mail:wanbang@wanbangresin.com WhatsApp:+8615053337101

WhatsApp:+8615053337101

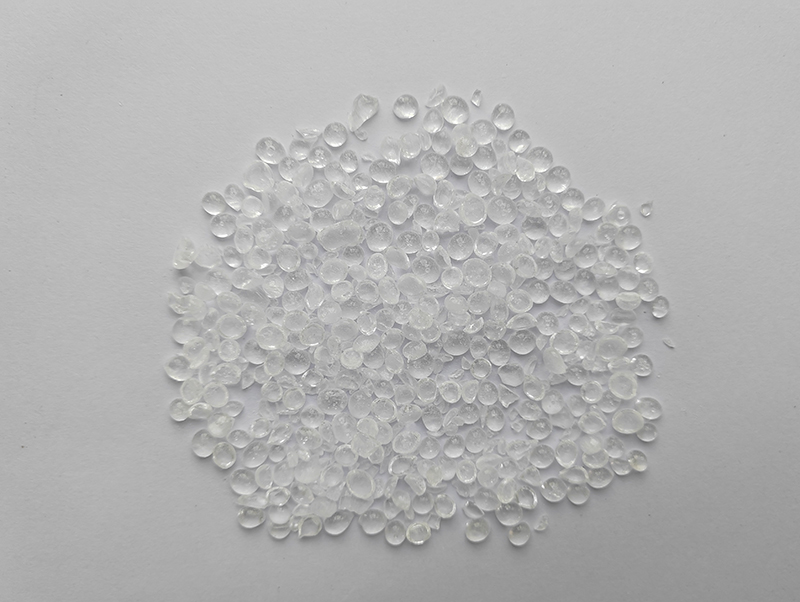

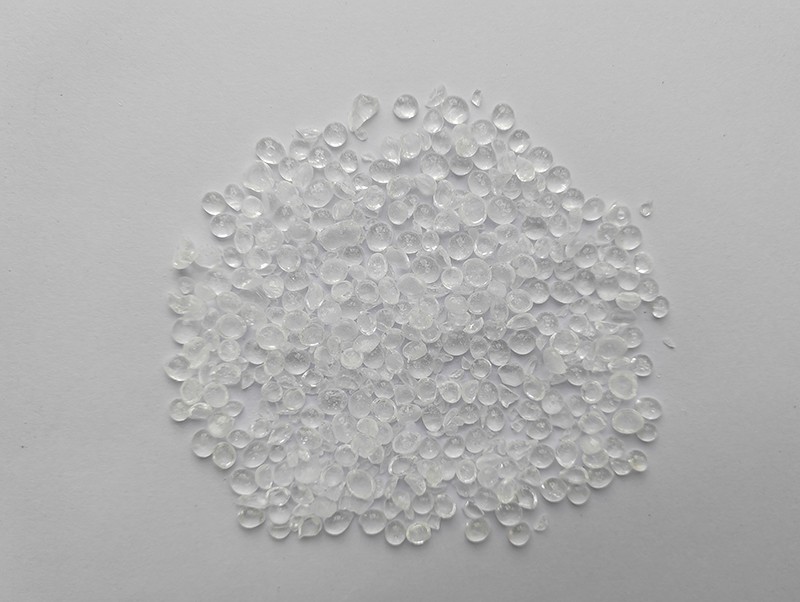

China C5 hydrogenated petroleum resin supplier : Shangdong Wanbang New Materials Co., Ltd.

C5 hydrocarbon resin manufacturer has a wide range of applications, high quality, low price, and multiple uses.Welcome to consult.