Language

▼

Language

▼

More Language

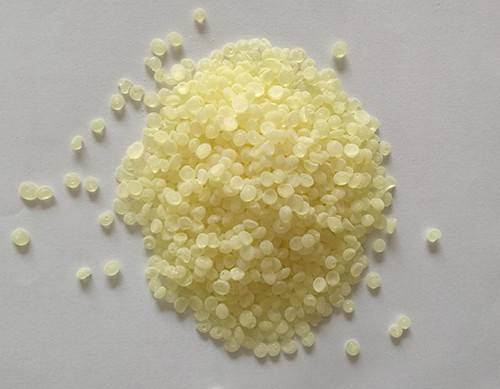

C5 petroleum resin for hot melt for hot melt flux has excellent heat resistance. This resin performs well in high-temperature applications such as hot melt adhesives and can maintain stable performance.Specifically, the heat resistance of C5 petroleum resin is reflected in the following aspects:

1. High temperature stability: Carbon five C5 petroleum resin for hot melt is not easily decomposed or deteriorated at high temperatures, and can maintain its original physical and chemical properties. This enables it to maintain stable viscosity and fluidity in applications such as hot melt adhesives that require high-temperature melting and coating, ensuring the coating effect and adhesive performance of hot melt adhesives.

Address:Linzi District,Zibo City,Shandong Province

Address:Linzi District,Zibo City,Shandong Province E-mail:wanbang@wanbangresin.com

E-mail:wanbang@wanbangresin.com WhatsApp:+8615053337101

WhatsApp:+8615053337101

China C5 hydrogenated petroleum resin supplier : Shangdong Wanbang New Materials Co., Ltd.

C5 hydrocarbon resin manufacturer has a wide range of applications, high quality, low price, and multiple uses.Welcome to consult.