Language

▼

Language

▼

More Language

Technical analysis of hydrogenated tackifying resins

I. Main types and raw materials

Hydrogenated petroleum tackifying resins:

C5 hydrogenated tackifying resins: Made from cracked carbon five fractions, produced through cationic polymerization and hydrogenation processes, with light color (iron cobalt color number <5#), softening point ≥95°C, suitable for hot melt adhesives, pressure sensitive adhesives and rubber products modification, can improve colloid aging resistance and compatibility.

C9 hydrogenated tackifying resins: Made by copolymerization and hydrogenation of carbon nine fractions and aldehydes, with a molecular weight of <2000, low brittleness and strong tackifying properties, suitable for paints, inks and paper additives, and excellent compatibility with elastomers such as SBS and SIS.

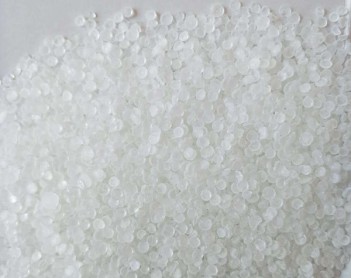

DCPD hydrogenated tackifying resins: Made from dicyclopentadiene polymerization and hydrogenation refining, with colorless and transparent particles, softening point 90-145°C, outstanding weather resistance (UV aging resistance >1000 hours), dedicated to high-end adhesives, automotive interiors and medical and health products.

Hydrogenated epoxy tackifying resin: TaiLuck-ST3000: Developed by Tohto Kasei, Japan, it achieves yellowing resistance (ΔE<2.0@UV aging) through hydrogenated bisphenol A epoxy tackifying resin. After anhydride curing, the glass transition temperature reaches 80℃, which is suitable for outdoor castings, wind turbine blades and LED packaging.

2. Core performance advantages Optical and weather resistance: Hydrogenated petroleum tackifying resin has stable color (YI≤2.2), transparency>90%, excellent UV resistance, and is suitable for packaging materials and automotive coatings with high appearance requirements. Hydrogenated epoxy tackifying resin has outstanding long-term aging resistance. The outdoor coating has no obvious yellowing after 10 years of use, and the anti-pollution performance is improved by 30%.

Mechanics and compatibility: C5 hydrogenated tackifying resin has high tackifying efficiency (peel strength increased by 20-30%), good compatibility with plastics such as EVA and PO, and can reduce the processing temperature of hot melt adhesive by 10-15℃. DCPD hydrogenated tackifying resin has a temperature resistance of up to 150°C, a dynamic bonding strength of >3.5 MPa, and is suitable for high-speed tire rubber and engineering plastic modification.

Environmentally friendly adaptation:

The VOC content of hydrogenated tackifying resin is <50 ppm, and it has passed RoHS and PAHs certification, meeting the environmental standards of medical-grade adhesives and food contact materials.

3. Application scenarios and selection suggestions

Colorless and odorless;

Excellent compatibility with substrates such as SIS, SBS, EVA, and APAO;

Good bonding performance;

Good weather resistance and thermal stability.

Adhesive field:

Hot melt adhesive and pressure-sensitive adhesive: C5 hydrogenated tackifying resin (such as DR-5300) optimizes colloid fluidity and is suitable for bonding non-woven fabrics, labels, and automotive interiors.

Medical-grade adhesive: DCPD fully hydrogenated tackifying resin (such as DR-5395) has a chromaticity YI <2.2, is non-toxic and odorless, and is specifically used for surgical patches and disposable sanitary products.

Coatings and inks:

Outdoor protective paint: TaiLuck-ST3000 tackifying resin is used as the base material, and the acid and alkali resistance of the coating film is increased by 50%, which is suitable for heavy corrosion protection scenes such as bridges and ships.

High-transparency ink: C9 hydrogenated tackifying resin is compounded with polyurethane solvent, the quick-drying property of the ink is improved, and the gloss of the printed product is ≥90 GU.

Plastic and rubber modification:

Engineering plastics: DCPD hydrogenated tackifying resin (DR-5340) is blended with PP/PE to increase the impact strength by 15-20%, which is suitable for automobile bumpers and home appliance shells.

Tire rubber: Hydrogenated C5 tackifying resin enhances the rubber-cord interface adhesion and extends the dynamic fatigue life by 30%.

Address:Linzi District,Zibo City,Shandong Province

Address:Linzi District,Zibo City,Shandong Province E-mail:wanbang@wanbangresin.com

E-mail:wanbang@wanbangresin.com WhatsApp:+8615053337101

WhatsApp:+8615053337101

China C5 hydrogenated petroleum resin supplier : Shangdong Wanbang New Materials Co., Ltd.

C5 hydrocarbon resin manufacturer has a wide range of applications, high quality, low price, and multiple uses.Welcome to consult.